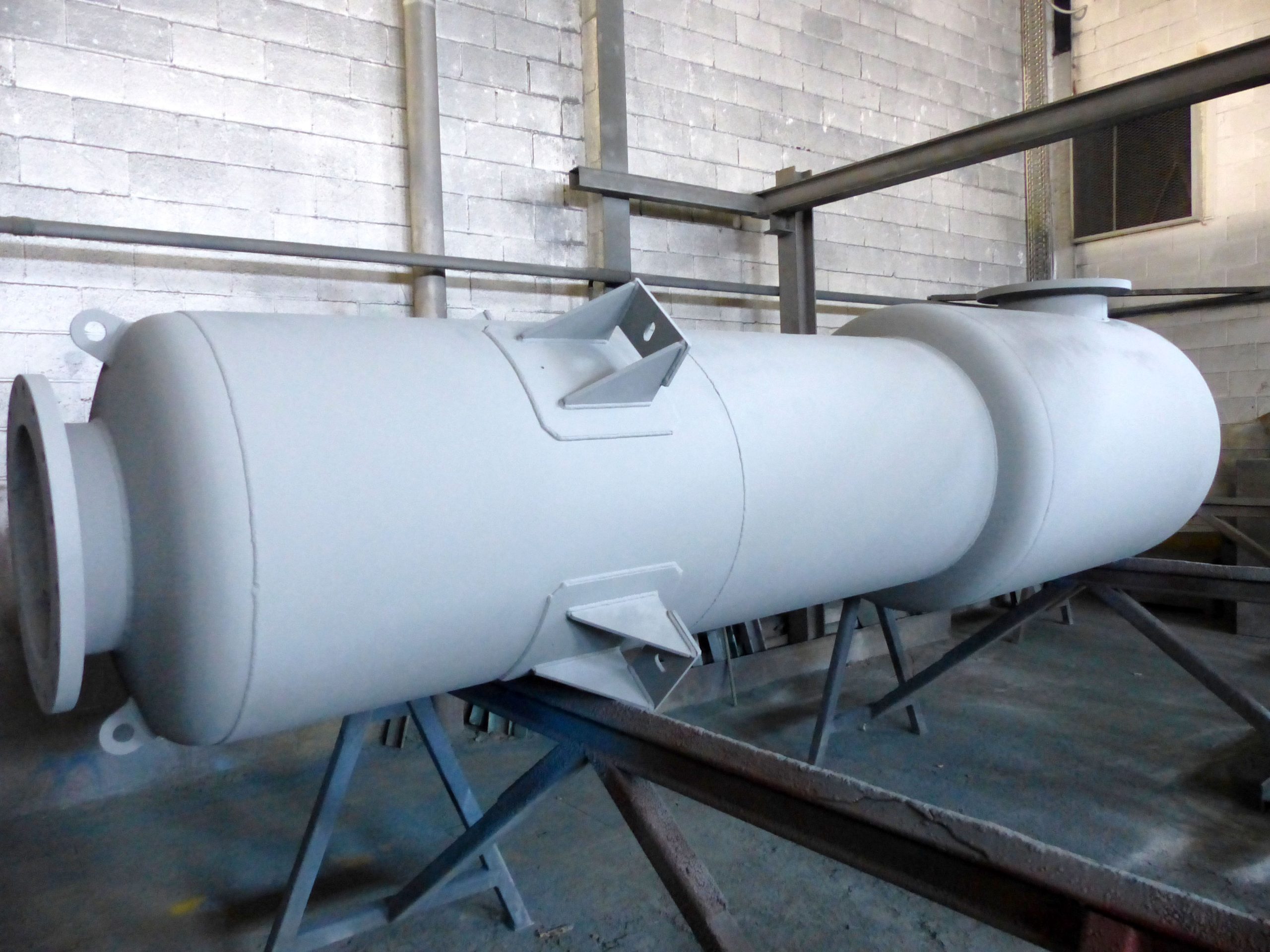

DIESEL/GAS ENGINE EXHAUST SILENCER | SILENCERS |

DIESEL/GAS ENGINE EXHAUST SILENCERS

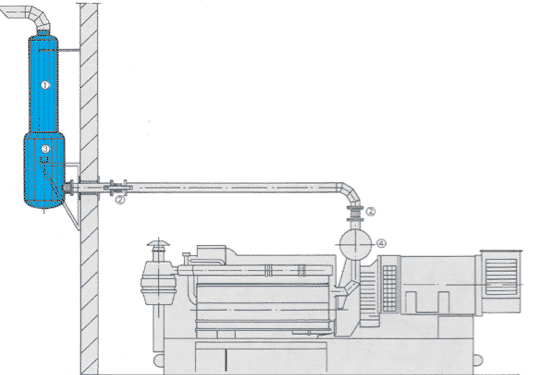

Silen Sistem model SM silencers are designed to reduce the noise produced by the exhaust gases of internal combustion engines and gas turbines.

Conceived and optimized by our R&D laboratories, they are based on the principles: reactive and absorbing wave attenuation.

Whatever the type of fluid (steam, air, oxygen, nitrogen), the gas pressure (impulsion, engine intake …) or the type of application, we have a range of silencers capable of providing noise attenuation that can reach 60 dB (A).

DIESEL/GAS ENGINE EXHAUST SILENCER OR ATTENUATORA OR WITH INTERNAL COMBUSTION

They are of the absorption type and reactive with a range of action that goes from 15 dB (A) to 60 dB (A). Silen y Sistem SM silencer solutions.

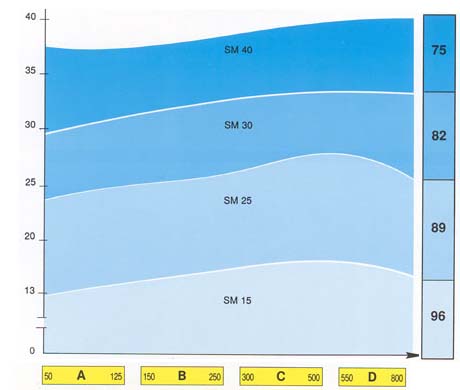

USE OF THE GRAPHIC

On the abscissa, place in zones A, B, C or D, the value closest to the diameter of the exhaust pipe.

On the ordinate, the required attenuation is chosen. The point of intersection helps us determine the silencer model and the corresponding data sheet.

The residual sound pressure level (Lp) was measured at 7 meters from a soundproof generator set, equipped with a 150 HP engine. Parasites were lower than the noises least 10 dB (A) to the average level of sound pressure.

Attenuation curves shown in each model indicate the insertion loss in decibels at different frequencies. The curves represent the expected dynamic insertion loss at each frequency using each type of silencer. Attenuated noise levels can vary due to multiple factors that influence attenuated noise, such as motor size, motor type, motor speed, and different frequencies.

The attenuation curves represent only the insertion loss to airborne noise and have no relation to the mechanical noise transmitted by the structure or the noise radiated by the pipe at the inlet of the muffler. The tests carried out in the study of each silencer calculates the insertion loss. Therefore, the curves in the graph can be used as a guide only to evaluate the total performance of the system, each case is unique and must be previously studied to make the appropriate silencer design.

To correctly size, the size and characteristics of the silencer, one of the most important factors is knowing the volume of exhaust flow (flow). The opening for the silencer flow area must be large enough to accommodate the exhaust flow inside without exceeding the back pressure allowed by the manufacturer of each engine. Insufficient silencer size can cause power loss and engine damage.

WHAT DATA IS NECESSARY WHEN DESIGNING AN ENGINE EXHAUST SILENCER?

- Engine exhaust flow (m / s)

- Maximum fluid temperature (ºC / ºF)

- Nominal diameter of the pipe

Proper muffler selection and size is of great importance to ensure optimal performance by ensuring acoustic performance, pressure drop, and all specific design criteria.

The correct choice of the Silen Sistem model of silencers, for the intake, as well as for the engine exhaust, is determined by the type of engine, the use that is given to the engine and the degree of attenuation required. If you have doubts about choosing the most suitable model for you, do not hesitate to contact our acoustic engineering department for advice.

PROPOSED RANGE OF EXHAUST SILENCERS

The selection of type and size of silencer is made taking into account:

- Sound pressure level of engine exhaust.

- Desired residual sound pressure level (at the same measurement point).

- Acoustic attenuation that is required as a difference from the previous levels.

- The ACOUSTIC PRE-DETERMINATION chart allows you to choose the silencer model for these systems.

We have standardized 4 models according to their spectral efficiency:

In general, the silencer models that we show in these technical sheets and tables usually solve a high percentage of cases, being a factory and also having an engineering department, at Silen and Sistem we are specialized in designs that meet specific and particular requirements. We manufacture the mufflers with various nozzle orientations, dual inlets and outlets, with multiple types of materials, etc.

The engine exhaust silencers that we have standardized will cover most applications, from diesel generator sets, industrial engines, internal combustion engines, most common exhaust gases, combustion engines, etc …